Round Bottom Drag Conveyors

The Powerflow round bottom conveyor is an addition to our highly popular and successful line of Powerflow En-Masse Conveyors. The Powerflow round bottom offers some features not available in other styles of conveyors. The reason most often given for choosing a round bottom style conveyor is cleanout. The close tolerance in the standard contour tail section and the fit of the flights in the trough ensure the minimum amount of material left in the housing between batches of material.

It is the intention of this section to familiarize the reader with the system in general and highlight the various components available to match your installation requirements. A simplified engineering section is included to evaluate conveyor performance but is very limited in its scope. The wide variety of materials, capacities, wear factors and feeding arrangements can have a large effect on conveyor and drive selections. We ask that you discuss your system requirements with us so we may suggest an arrangement best suited to your needs.

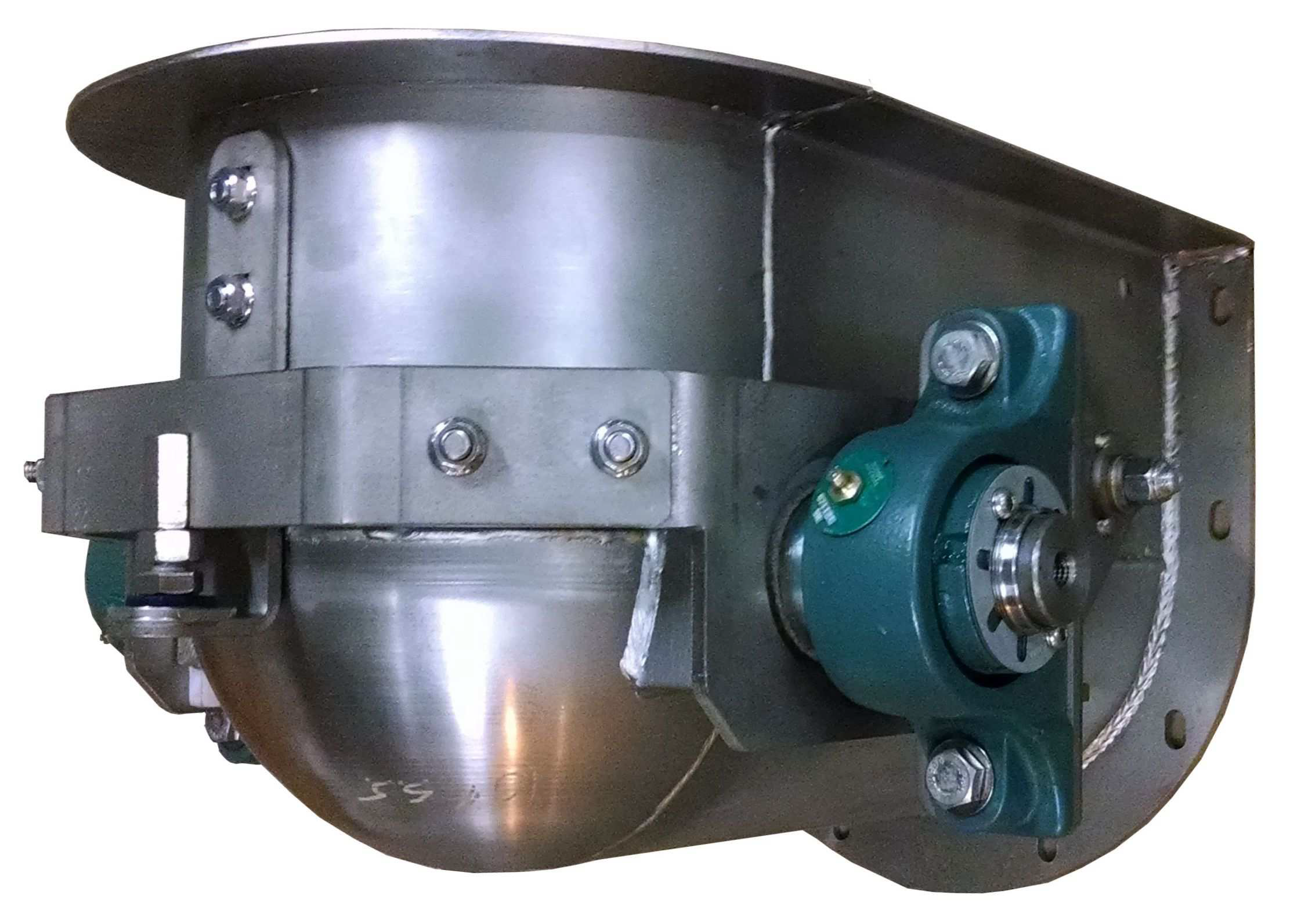

New Floating Tail Design Option

Chain and flight conveyors with fixed tail shaft bearings must provide some clearance, usually 1/4“ or so, between the chain flight and the tail section floor to minimize the possibility of a jamming material between the flight and floor. This has the disadvantage of the flight leaving material in the tail section after the conveyor feed is shut off.

Description:

Our new floating tail section allow the UHMW flights to constantly scrape the area under the tail sprocket, generally leaving just dust for the wiper flights to clean. The shaft movement is field adjusted to allow for flight wear over time. An obstruction between the flight and floor will move the shaft upward to allow the flight to go over it and let the next flight deal with it.

Operation of a round bottom conveyor varies greatly from one application to another. Some conveyors are operated much like a standard en-masse conveyor where the trough is full of material up to the top return chain idlers and the entire mass moves along with the chain. Other applications, such as those going up a significant incline, may have the trough only partially filled and each paddle moves an individual pile of material along with it. Any given conveyor application will behave differently depending on the type of material handled so we strongly recommend that all but the most simple applications be referred to the factory for analysis.

The conveyor can be fed by one of two methods: Controlled Feeding or Flood Feeding.

A control fed conveyor has the capacity determined by a feeding device such as a bucket elevator, another conveyor or a process machine. The conveyor speed is set so that the trough conveying area is never more than 95% full.

A flood fed conveyors capacity is determined entirely by the speed of the conveyor. There are three possible methods by which a round bottom conveyor may be flood fed. It is possible to flood the trough by dumping right into the top and passing through the top chain. This requires an extensive distance between the inlet and the tail however so this method is rarely used. More often the material is fed through a by-pass inlet or onto a pan feeder. Use of a by-pass inlet allows the conveyor to be fed right next to the tail section.

| Name | Type | Size |

|---|---|---|

| Round Bottom Conveyor Brochure | brochure | 0 bytes |