EDI Distributor Control

- Positive

The EDI control uses an absolute positioning, dual sensor pickup that uniquely identifies each spout position. No “counting from home” is required. - Trouble free

Each spout is driven by a variable torque clutched drive system that protects the distributor and drive system from damage in case of jammed spouts. The unique drive system never needs adjustment. - Fast positioning

After initial installation the controls do an automatic, one-time, self-teach routine to learn the characteristics of the distributor to which it is connected. The spout then rotates using the “shortest path” to the desired outlet. - Run it your way

The operator may field assign bin numbers and names to all positions and use “speed dial” buttons for up to six positions. Additionally, the keypad-display terminal can be mounted remotely from the control panel, in a more convenient location for the operator. - Competitive

In most cases the complete system, installed and wired, is less expensive than a comparable limit switch system.

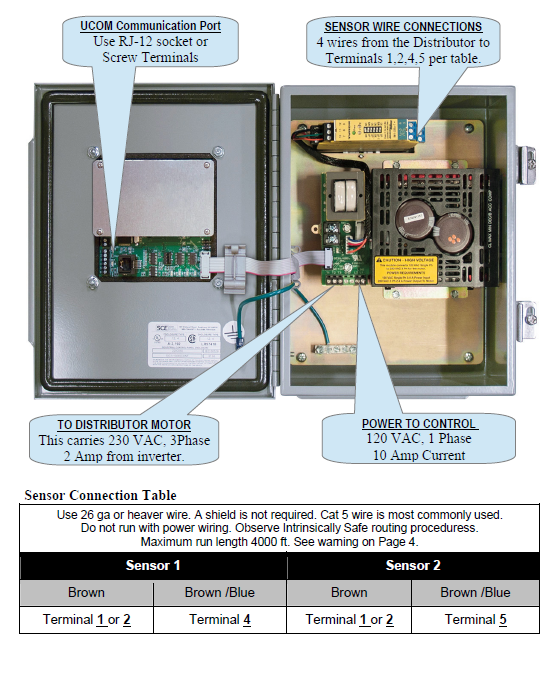

Schlagel’s EDI Controls require 110v 50/60 Hz control power and appropriate 3-phase motor wiring from the internal EDI controlled inverter. The controls offer a wide variety of features that enhance the operation of your distributor.

- Microprocessor-based intelligent control.

- Rapid, closest path positioning to any duct.

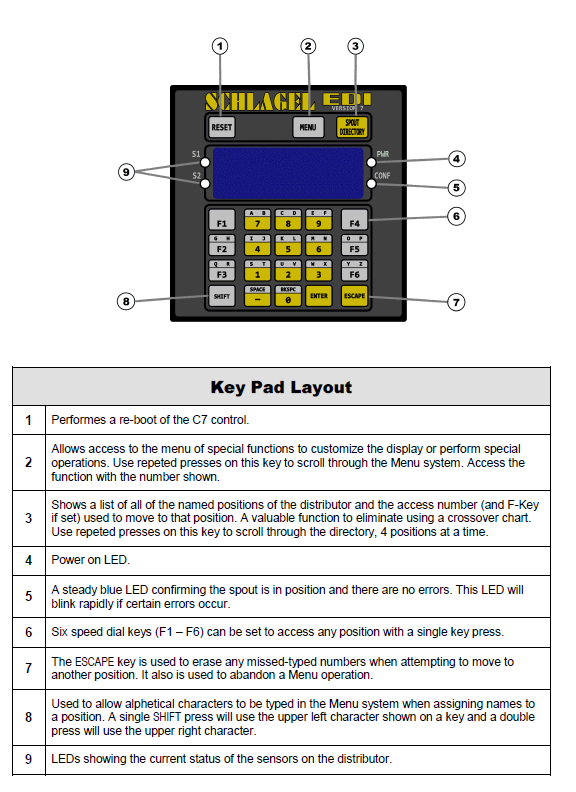

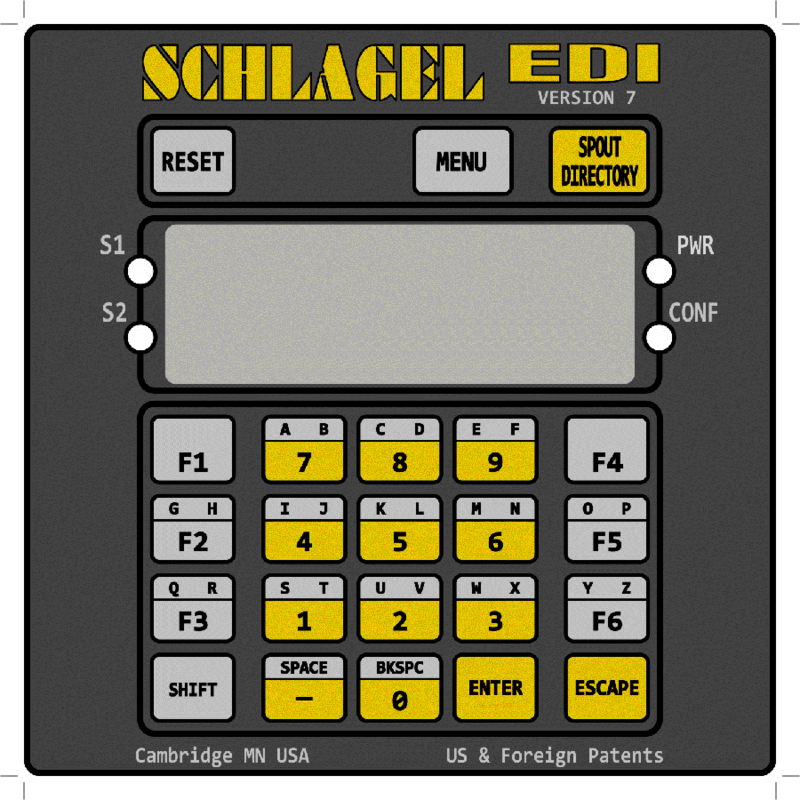

- Large 4 line fluorescent display.

- Tactile feedback keyboard.

- Keyboard-display unit may be placed at a remote location, up to 50 feet from control unit.

- Absolute spout positioning. Each duct is uniquely identified. No home synchronization is required.

- Remembers all distributor parameters incase of power loss; then verifies the spout position when power is restored.

- Single button access is available for up to six often used positions

- User programmable access numbers may be assigned to all positions. No cross reference charts necessary.

- A user programmable name of up to sixteen characters may be assigned and displayed for each spout position.

- A one time, automated setup procedure allows the control to “LEARN” all parameters of the distributor, even correcting for reversed motor wiring.

- Inexpensive 4-wire cable carries all position signals for each spout from any size distributor. This cable can be routed in a hazardous area without an enclosure.

- No mechanical adjustment of the distributor is necessary.

- Torque limiting clutch prevents damage to the spout and drive in case of a jam from a foreign object.

- Motor enclosures are the only consideration when installing in hazardous environments.

- All electrical components including motor starter and thermal protection (but less disconnects) are included.

- Requires 110v 50/60 Hz control power and appropriate 3-phase motor power supplies.

- Two auxiliary outputs available with optional relay interface.

- Built-in error and diagnostic aids.

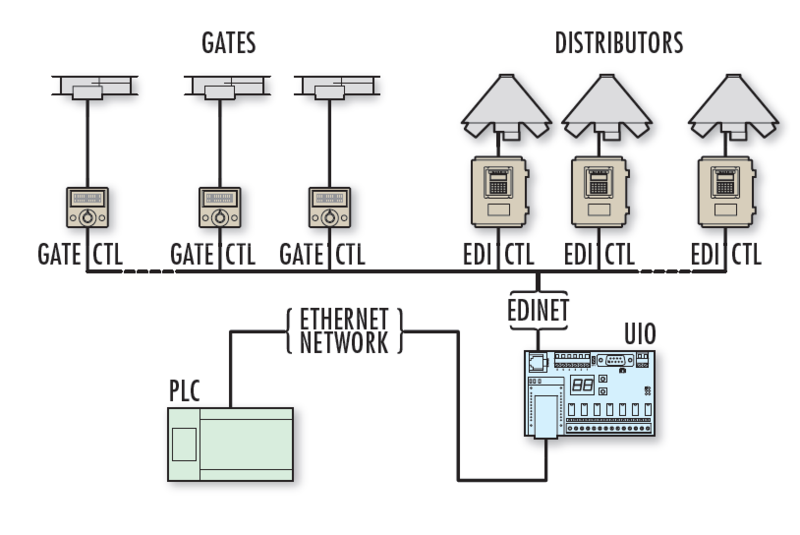

- Optional interfaces to PLCs and indicator lamps are available.

IMPORTANT WIRING NOTES

| WARNING |

|---|

| Make sure the wiring meets all applicable regulations and codes including local and national standards and codes. High voltage can kill or seriously injure personnel. All maintenance personnel must be trained and follow the Lockout/Tagout procedures established by the facility management. |

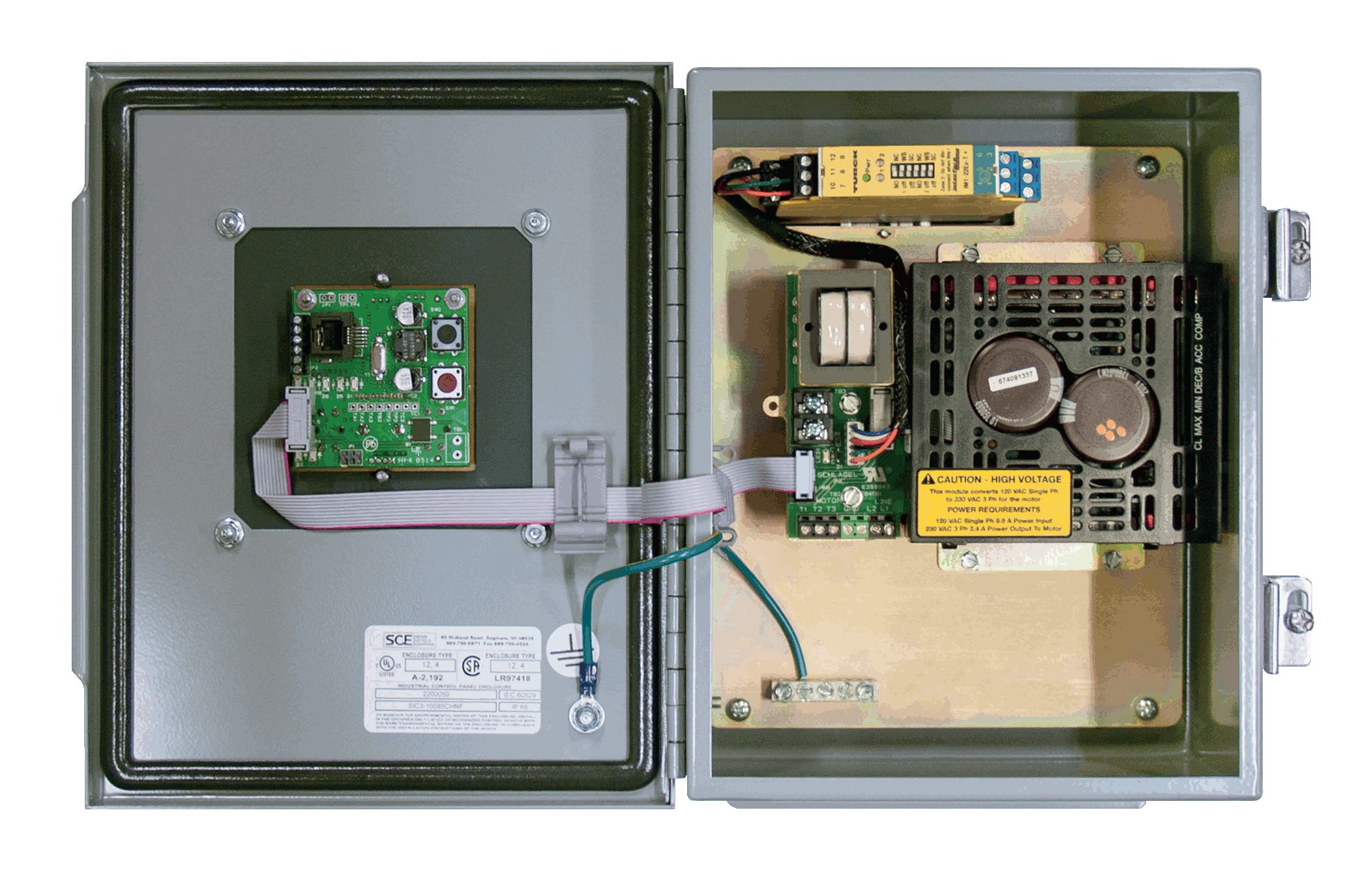

- The C7 control is weather and dust tight and mounted in a 10x8x5 NEMA 12 enclosure.

- UL/C-UL listed panels are available as an option

- Sensor wiring is Intrinisically Safe (IS).

- Sensor wiring cannot be run in conduit with the motor power or any non-IS wiring. If it is, two things will go wrong:

- Electrical noise will interfere with the sensor signals causing error messages.

- IS safety compliance is lost.

- See the UIO installation manual for communication port connection information

Click for Wiring Instruction Video

The EDI-C7 is designed around the fact that plant automation is becoming a necessity instead of just a convenience. The UIO sits between the PLC and multiple EDI distributor and/or VGC gate controls. The UIO then talks directly to PLCs using a serial or Ethernet connection. Many PLC protocols are supported so that operation of the distributors is performed without writing a single rung of PLC code. Most importantly, any error information is communicated from each distributor to the PLC so the necessary remedial action may be taken. The EDI-C7 network is fully compatible with existing EDI networks. Any distributor with an earlier version of the EDI control may be upgraded to take advantage of the C7 features.

See UIO Documentation Below for more details.

Our standard configuration for VGC or EDI is mounted in a 10" x 8" x 5" Deep NEMA 12 Enclosure.

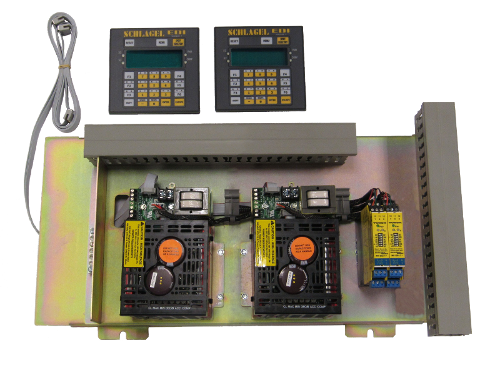

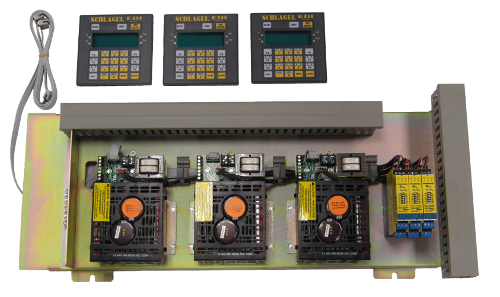

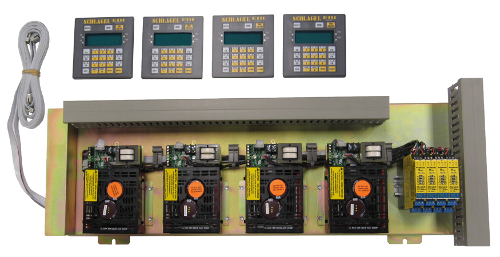

EDI / VGC Components can also be mounted on optional Multiple Module Backplanes ready to install in customers own Enclosure

2 Position Module

3 Position Module

4 Position Module

Custom display flanges can be designed to meet customer panel size.

EDI / VGC Components can also be factory mounted in an optional multiple module enclosure

| H X W X D | NBR. OF CONTROLS | H X W X D | NBR. OF CONTROLS |

|---|---|---|---|

| 10 X 8 X 5 | 1 | 36 X 36 X 8 | 12 |

| 16 X 10 X 6 | 2 | 48 X 30 X 12 | 12 |

| 24 X 20 X 8 | 4 | 48 X 36 X 8 | 16 |

| 36 X 30 X 8 | 9 | 60 X 36 X 8 | 20 |

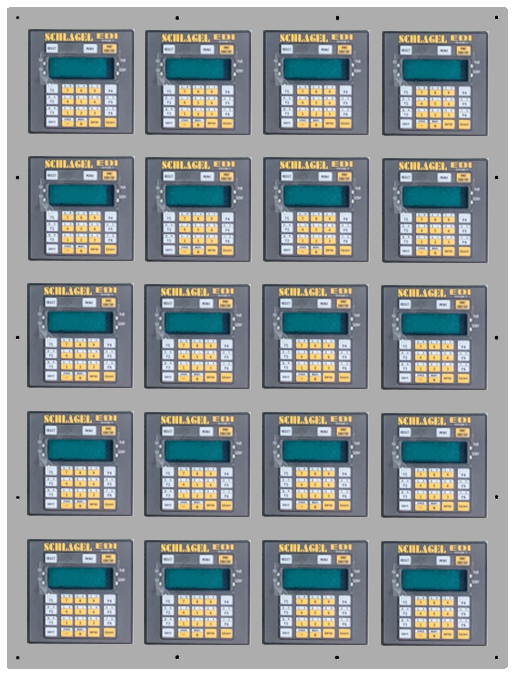

Shown above is a pre-wired 48" x 36" x 8" NEMA 12 enclosure holding 16 complete EDI drives and controls. This Enclosure can include an Ethernet UIO and associated communication wiring to the controls for PLC automation. These panels may be just partially populated with controls to allow for future expansion

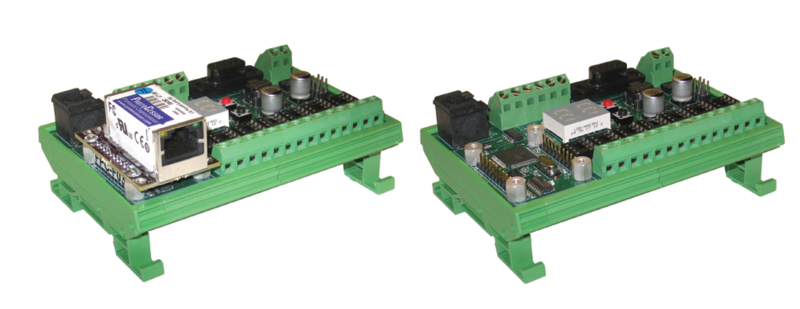

- Universal I/O (UIO)

The Multi-function UIO Interface Module can handle digital switching as well as network control. It can communicate directly to PLCs using serial or Ethernet media and several language protocols including DF1, Modbus-RTU, Ethernet/ IP and Modbus/TCP. It can also be used for direct digital switching of relays, starters, alarms, solenoids or other discrete plant devices.

- Remote Keypad/Display Kit

This kit will allow a second EDI keypad/display to be mounted remotely from the control cabinet. Use this accessory when it is necessary to operate the EDI Distributor from more than one location. The kit includes the EDI display console and adapter. A display mounted in a 8" x 10" NEMA 12 enclosure is also offered.

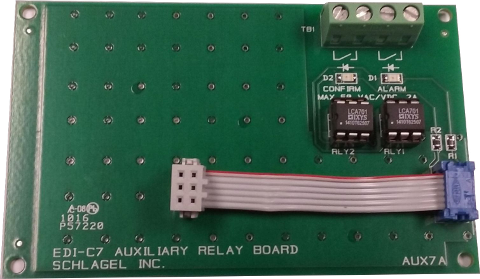

- Auxiliary Alarm Board

All EDI-C7 users can take advatage of the Auxiliary Alarm Board, Aux7. This board screws to the back of the C7 and provides 2 solid state relays. These 2 relays are used for either an "Out of Position" Alarm function or an "In Position" Confirm function.

The Relay outputs can be used to activate a device such as an audible alarm, indicater lights, or a mechanical starter. Max 50 VAC/VDC 2A

- Wiring Accessories

We have the cables and hubs required for a complete EDINet installation. The cables have RJ-12 plugs on each end and come in stock lengths of 5’, 10’ and 25’ and 50’ lengths. Hubs are available with 6 or 12 ports.

All EDI distributors manufactured since 1994 can be upgraded to operate from the latest version of the EDI control called C7.

The earlier versions of EDI controls used state-of-the-art technology to become the most reliable and affordable electric distributor in the market. Technology has advanced tremendously in the last 20 years and so has the EDI. We have completely redesigned the operating electronics, taking advantage of the newest processors and micro components to create the C7 control we use with the distributors we ship today.

The C7 eliminates all of the electro-mechanical devices on the earlier EDI controls. No mechanical functions (except for the motor turning the spout) take place during the distributors’ operation. There is no longer maintenance requirements or the possibility of a mechanical malfunction of those components.

You can upgrade your older EDI control to C7. Here are a few reasons for doing so:

- Eliminate the brake motor.We now use a standard TENV or IIG 3 phase motor.

In order to precisely position the spout, the motor can’t be allowed to coast to a stop. That is why we used a brake motor in the older versions. But the brake required adjustment or replacement after time, and in cold weather a heater was required on the brake operator to prevent the brake disk from freezing. The C7 uses standard 3 phase motor eliminating the mechanical brake components. This also removes the possibility of the brake pad freezing. - Eliminate the reversing starter. C7 uses electronic control of the motor

A mechanical reversing starter has a difficult life. There are many contacts that open and close, arching from the high inrush currents and reducing the life of the contact at each operation. There is also the mechanical interlock that moves back and forth to prevent both sides of the starter from engaging at the same time causing a catastrophic short circuit. Slamming full voltage to the motor and brake also creates an impact on the gearing and other mechanical components of the drive. The C7 electronically controls the entire operation of the motor and uses soft start/stop techniques reducing the mechanical wear on the drive components. - Dust and moisture proof operator. The C7 has a sealed keypad/display control.

We continue to supply the same size, high visibility, VFD 4-line display and 20 key keypad but now it is sealed. When properly mounted in a NEMA 12 enclosure it is suitable to operate in weather from –20f to 120f, and can endure rain, ice and snow. - Compatibility and conversion. All features of the C7 will work on our older EDI controlled distributors.

The C7 control will work on any EDI distributor we have produced. It is smaller than previous models but can be supplied on a back plane that will fit your existing enclosure. When converting to C7, a new motor is generally used but you can use your existing brake motor if you remove the brake components and can rewire it to accept 230 volts, 3 phase. 3 phase power is no longer supplied to the control. Instead, a single 120 volt 10 Amp supply powers the entire EDI drive. The C7 control electronics create the 3 phase power for the motor. - Cost. Like most electronics, as technology improves cost goes down.

The reverse applies with old technology. The cost of those devices goes up with time as parts become more scarce or unavailable. Every day it becomes less expensive to upgrade rather than repair or replace old parts. - Convenience. Take advantage of the extra features found on the C7.

You can still name your positions and access numbers for each spout outlet but now we have added a Spout Directory key so you can quickly look through the on screen list to find the position you want. A new Menu key allows direct access to many of the customizing functions available in the C7 control.

Faster, smarter and reliable are the trademarks of the EDI-C7 control. The list of C7 features is too lengthily to list here but they are all available if you decide to upgrade your older control. We are committed to keeping a very critical part of your operation up to date with the latest technology and industry leading service and technical support. Please contact us with any questions or to get an evaluation and quotation on your upgrade.

| Name | Type | Size |

|---|---|---|

EDI Controller |

||

| EDI-C7 Installation Manual | manual | 752 KB |

| EDI-C7 Operators Manual | manual | 396 KB |

| EDI-C7 Clean Sweep | documentation | 119 KB |

| EDI-C7 Auxiliary Alarm Aboard | documentation | 194 KB |

| EDI Control Brochure | documentation | 4 MB |

Univerasal I/O |

||

| UIO Setup Utilities | zip | 1.09 MB |

| UIO Ethernet Operators Manual | manual | 2.47 MB |

| UIO Digital Operators Manual | manual | 731 KB |

Previous Version EDI Manuals |

||

| Version 1 - 2 EDI Control | manual | 620 KB |

| Version 3 EDI Control | manual | 93 KB |

| Version 5 EDI Control | manual | 371 KB |

| Version 6 EDI Control | manual | 3.12 MB |