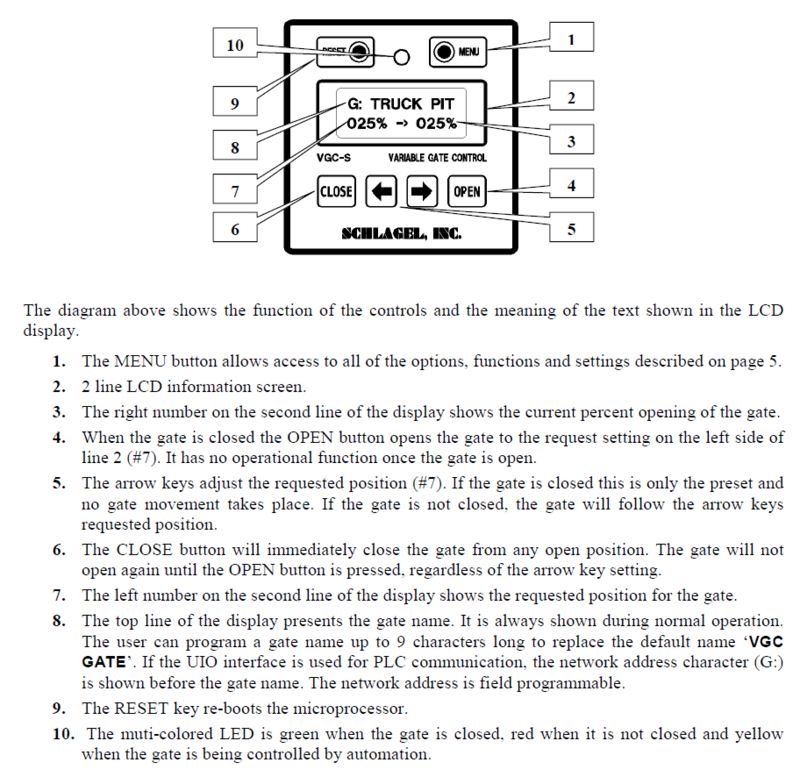

VGC Control

The economical ‘VGC’ is a complete variable position controller for an electrically operated R&P slide gate. The ‘VGC’ can be used with either a TENV or IIG 1/2 HP 3 phase motor and is fast acting with ample power. A gate with a ‘VGC’ uses intrinsically safe inductive sensors in place of the mechanical switches. It is useful for pit gates, bin discharge to reclaim conveyor, dryer feed control, and bypass metering gates, or anywhere a metered gate is desired. There is also a special setting for gates that only operate fully open or closed.

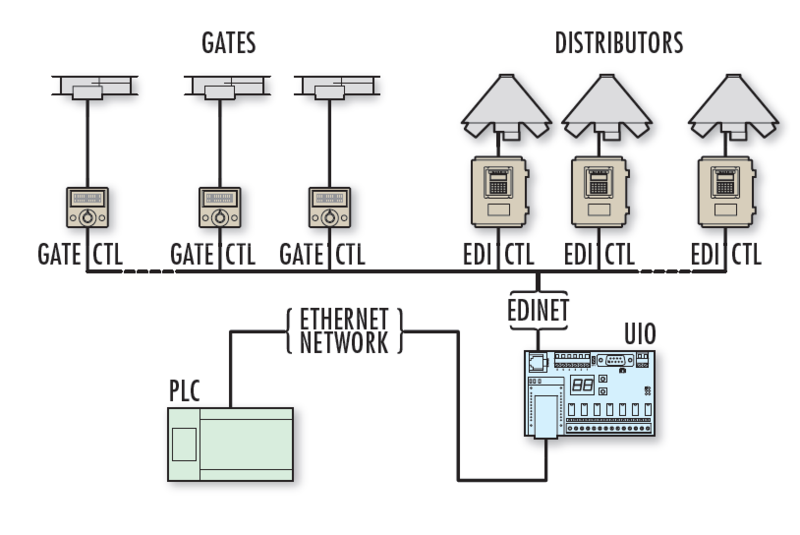

The VGC is designed around the fact that plant automation is becoming a necessity instead of just a convenience. The UIO sits between the PLC and multiple EDI distributor and/or VGC gate controls. The UIO then talks directly to PLCs using a serial or Ethernet connection. Many PLC protocols are supported so that operation of the Gate is performed without writing a single rung of PLC code. Most importantly, any error information is communicated from each VGC Control to the PLC so the necessary remedial action may be taken.

See UIO Documentation Below for more details.

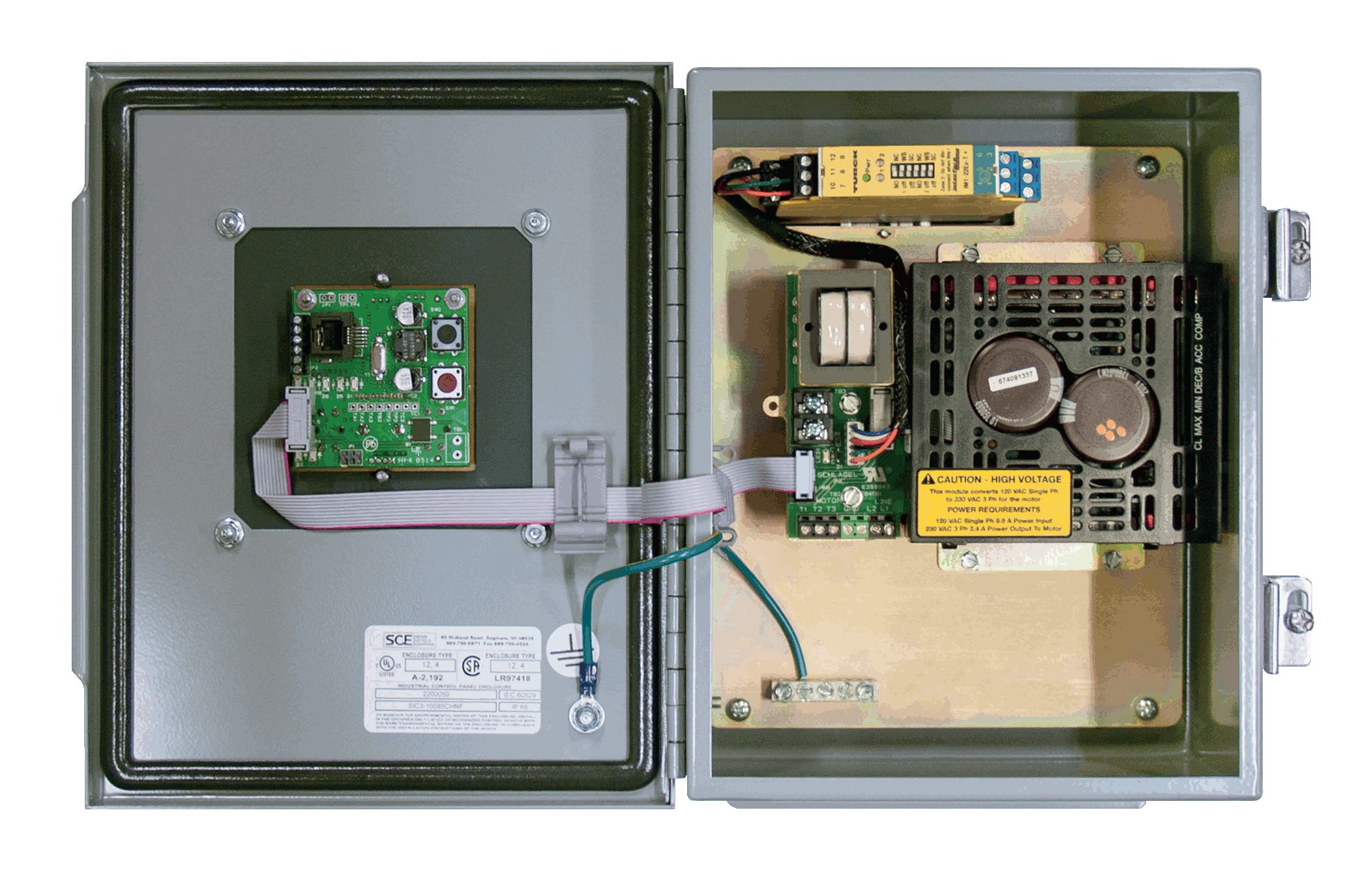

Our standard configuration for VGC or EDI is mounted in a 10" x 8" x 5" Deep NEMA 12 Enclosure.

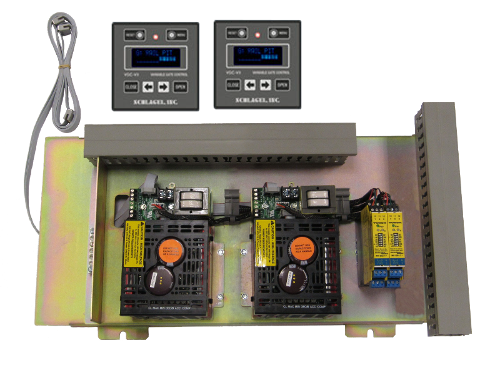

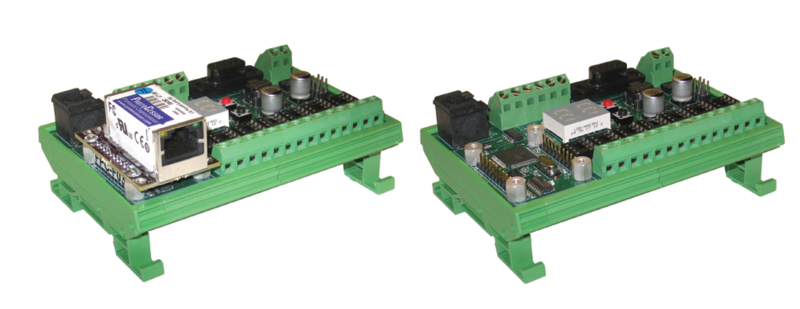

EDI / VGC Components can also be mounted on optional Mutiple Module Backplanes ready to install in customers own Enclosure

2 Position Module

3 Position Module

4 Position Module

EDI / VGC Components can also be mounted on optional Mutiple Module Backplanes ready to install in customers own Enclosure

Shown above is a pre-wired 4' x 3' x 8" NEMA 12 enclosure holding 16 complete VGC drives and controls. This Enclosure can include an Ethernet UIO and associated communication wiring to the controls for PLC automation. These panels may be just partially populated with controls to allow for future expansion

- Universal I/O (UIO)

The Multi-function UIO Interface Module can handle digital switching as well as network control. It can communicate directly to PLCs using serial or Ethernet media and several language protocols including DF1, Modbus-RTU, Ethernet/ IP and Modbus/TCP. It can also be used for direct digital switching of relays, starters, alarms, solenoids or other discrete plant devices.

- Wiring Accessories

We have the cables and hubs required for a complete EDINet installation. The cables have RJ-12 plugs on each end and come in stock lengths of 5’, 10’ and 25’ and 50’ lengths. Hubs are available with 6 or 12 ports.

| Name | Type | Size |

|---|---|---|

VGC Controller |

||

| VGC-V3 Installation | manual | 0 bytes |

| VGC-V3 Operator | manual | 0 bytes |

| VGC-V2 Installation | manual | 0 bytes |

| VGC-V2 Operator | manual | 0 bytes |

| Manual to VGC Conversion | manual | 0 bytes |

Univerasal I/O |

||

| UIO Setup Utilitys | zip | 0 bytes |

| UIO Operators Manual | manual | 0 bytes |