R & P Valves

R&P Valves are available in two operator styles, synchronized and non-synchronized. The most commonly ordered synchronized style allows the use of one manual, air, hydraulic or electric operator and a set of synchronizing sprockets that closes one slide as the other one opens. This style has the slides overlapping at the valve crotch giving the ultimate in leak-free valve performance. The other less common non-synchronized style requires independent operators to move each slide, thus offering the possibility that the valve could be used as a shut-off with both slides closed or as a “splitter” with each slide partially open.. The slides in this style butt up against the valve crotch rather than overlapping.

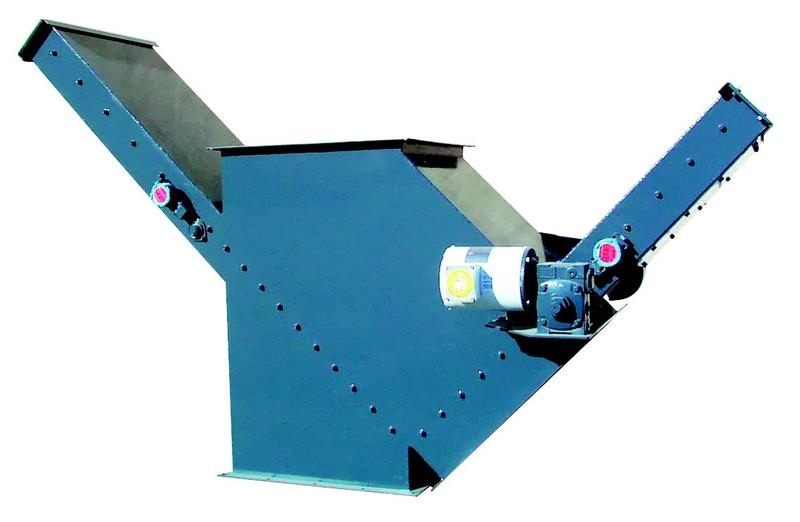

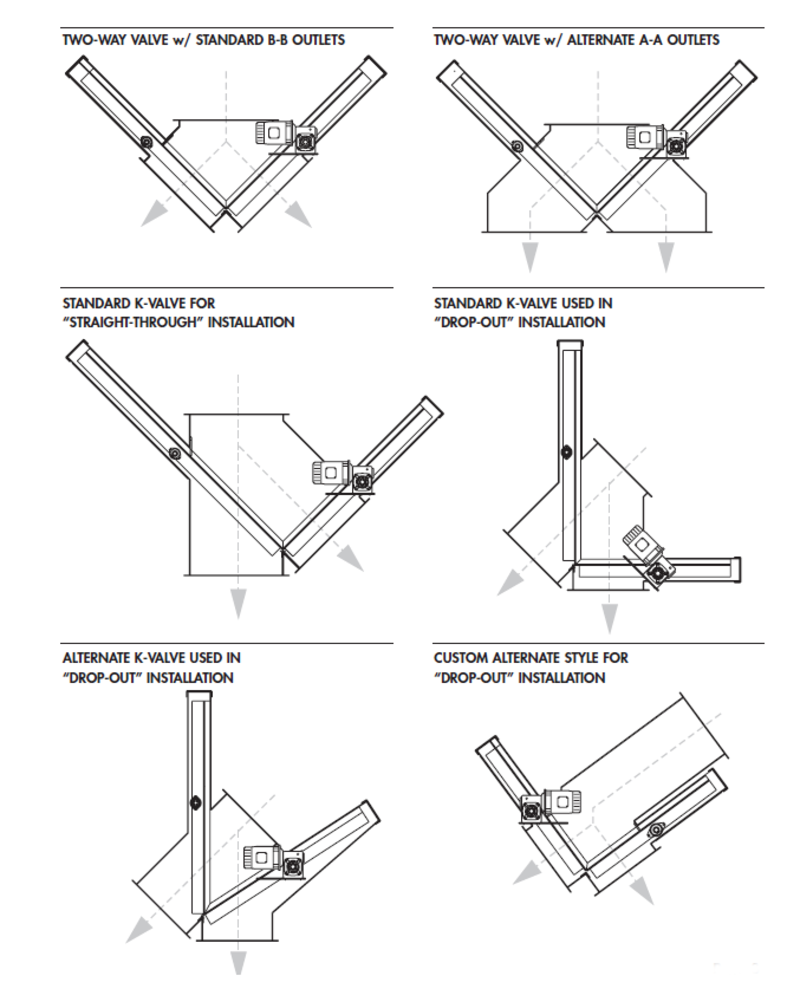

Two common physical configurations are used. The Two-Way (or “pants-leg”) style with standard B-B or optional A-A style outlets and the K-Style. The K-Style is normally used in a vertical position allowing grain to run straight through or divert it off at an angle. It can also be used as a “dropout” in an angled spout. It is important to notify your Schlagel sales representative at time of order which way you intend to install your K-Style R&P Valve as that will dictate the appropriate locations of wear liners. We do offer special models for dropout applications if you are concerned with the amount of material that will sit in the “pocket” when running straight through on the dropout style. This special configuration reduces this pocket but it can not be eliminated entirely.

| Name | Type | Size |

|---|---|---|

Installation & Operation |

||

| R & P Installation | manual | 0 bytes |